See also our repair kits for BMW Disa

Vanos Seals Failure Affected Automobiles

Vanos BMW Repair kits

Purchasing

– Shopping cart and payment processing provided by PayPal;

– Purchase with PayPal account or credit card.

Shipping (per purchase/shipment)

– Standard International Shipping.

Warranty

– Limited 360 day warranty.

See also our repair kits for BMW Disa

vanos bmw, repair kit vanos bmw, repair bmw vanos, double vanos, Twin Vanos Repair Seal Kit, doppel vanos, disa bmw, repair disa, dual vanos, single vanos, ring vanos, oil seals vanos, 11 36 1 440 142, 11 36 1 748 036, 11 36 1 748 819

BMW 6-cylinder Vanos Seals Solutions

Do you own one of the below BMW 6-cylinder cars, 1993-2006? If so then your vanos, engine variable valve timing unit, is most likely failing. These vanos units have been consistently diagnosed to fail due to deteriorating piston seal O-rings. The O-rings are made of a material that is failing in the engine environment. This causes the vanos piston seals to lose their sealing function and for the vanos unit to fail.

BMW does not provide the vanos seals separately. It sells rebuilt vanos units for ~$800. New rebuilt vanos units are supplied with the same failing O-rings and have been found to significantly fail in 20k miles (32k kilometers).

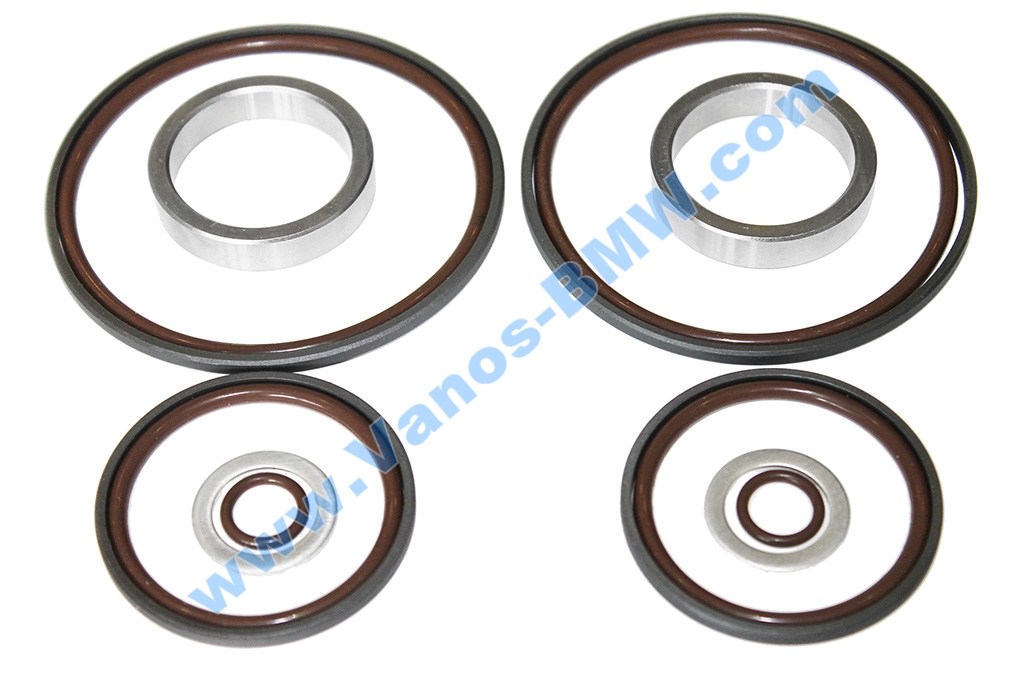

Vanos seals repair kits are now available. They incorporate upgraded O-rings to address the failure mode and replacement Teflon seal rings.

Vanos BMW Seals Failure Symptoms

Overall loss of torque and power, particularly in the lower RPM range, < 3k. Bogging then surging at 3k RPM. Uneven power distribution and RPM transition. Engine hesitations in the lower RPM range, < 3k. Louder idle and intermittent idle RPM hiccups. Difficult takeoffs. Loss of power and bogging when AC on. Increased fuel consumption. Vanos fault codes.

Double vanos cars with the M52TU engine (98/99-00) experience cold weather cold start idle jolts and possible stall.

Vanos Seals Repair Benefits

Overall increase in torque and power, particularly in the lower RPM range, < 3k. Resolution of bogging then surging at 3k RPM. Smooth even distribution of power and RPM transition. Resolution of engine hesitations in the lower RPM range, < 3k. Quiet stable idle. Smooth easy takeoffs. Improved performance when AC on. Reduced fuel consumption, by ~10%. Resolution of vanos fault codes.

Resolution of double vanos M52TU engine (98/99-00) cold weather cold start idle jolts and possible stall.

Rattle solution Vanos BMW

This vanos, like most vanos designs, can develop a rattle. The vanos rattle is caused by wear in the variable valve timing helical (slanted) gears. These gears are found on the camshaft, camshaft sprocket, and splined shaft which attaches to the vanos. The helical gear wear allows the camshaft to have lash movements that engage the splined shaft axially. At certain RPMs these movements resonate and engage axial play (free space) and cause associated components to hit and rattle. The axial play that facilitates the rattle is found on the helical gears and the vanos piston bearing. Replacing the helical gear components is expensive and the gears will wear again and the rattle will return. Removing the vanos piston bearing axial play significantly reduces the rattle to the point where it’s barely heard or not heard at all in the passenger compartment.

|

www.Vanos-BMW.com/BMW-VANOS-rattle-fix.mp4 |

www.Vanos-BMW.com/BMW-VANOS-problem-solved.mp4 |

Removing the vanos piston bearing axial play significantly reduces the rattle. Also replacing the helical gear components (splined shaft, camshaft, sprocket) is expensive and the helical gears will wear again. Thus removing the vanos piston axial play is a practical approach to addressing the rattle problem. Furthermore, per bearing specification and consultation with bearings companies, there should be no bearing axial play and a notable axial pre-load (tightness) should be present.

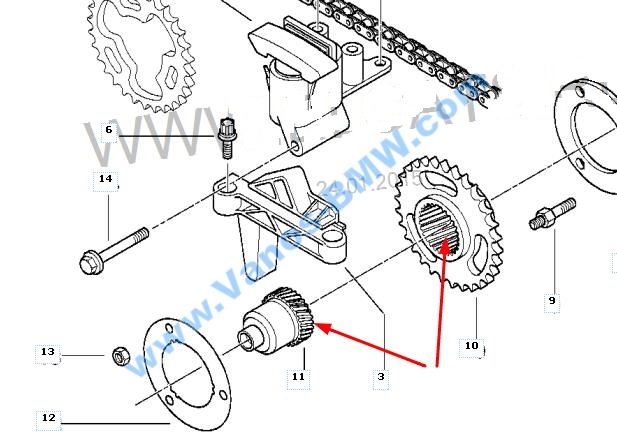

The vanos piston bearing is made of a thick washer and two thrust (roller) bearings. The washer if mounted to the splined shaft and the two thrust bearings sandwich the washer facilitating the washer to rotate at camshaft speed. The washer and two thrust bearings are incased in a ring and two ring outer washers. The complete bearing is housed inside a piston cavity and is closed off with a piston bolt/cap.

Removing the bearing axial play requires modifying or replacing at least one bearing component. The thrust bearings are a standard part and are manufactured to tight tolerances. It’s not feasible to modify or replace them. The ring and center washer are non standard parts and are manufactured to loose tolerances. The ring height can be reduced or the center washer height can be increased to remove the bearing axial play. The ring has been found to have a large height variation and the washer has been found to have a smaller height variation. Due to these findings, it’s more effective to replace the ring. A bearing adjustment can be made at installation to address any minor axial fit variation.

The bearing ring and center washer were assessed by a metallurgical consulting firm. The parts were assessed for their material makeup, hardness including micro depth hardness, manufacturing process and finish.

As a solution to the vanos rattle problem a replacement vanos piston bearing ring is manufactured to the same specification as the original bearing ring but with a shorter height and a very tight height tolerance. The other ring dimensions are also manufactured to tight tolerances.

The bearing ring is a difficult and expensive component to manufacture. It’s made from a special bearing steel and hardened to a high hardness. All its surfaces are ground. This technique allows for machining hard parts to a high dimensional tolerance and a polished surface.

Problem number 1

The main cause of the problem is that the material BUNA (rubber) which are made of bearing seals piston actuator system vanos has insufficient resistance to heat and corrosive media, whereby it eventually hardens and loses its elasticity.

As a consequence there are gaps leading to leakage mechanism inside, resulting to rotate the camshaft requires much more oil pressure which is possible at higher speeds, and the older your Vanos the higher the required momentum, and when the oil pressure is not enough to turn the shaft stops Vanos work in principle.

The service life of the new factory Vanos is not large, the deterioration of the already noticeable on the run in the 50000 Km.

In the photo below you can see that the removal of the O-rings have long ceased to have anything to do with the rubber 🙂

Policy, BMW does not imply the production and sale of repair kits, problem solving proposed replacing the entire unit as a whole, the value of the node vanos is $ 1,000 or more + cost of the work.

We have a solution to this problem!

We produce and sell the new O-rings made of materials that are superior in performance materials used in the original executive Vanos nodes.

We use Teflon and Viton (patented name of the company Du Pont Nemours and the Company (USA)) and bearing steel.

The use of high quality materials increase the life of the at times!

Problem number 2 (chirping noise Knocking)

Another problem is that the washer and needle bearing mounted in the piston Vanos deteriorates over time, which could result in backlash and noise of the engine!

This problem also can be solved only need to replace the steel ring (cage) typesetting bearing on the new (especially manufacturing), it will eliminate the gap, and thus disappear and noise.

Problem number 3 – Mechanical jam

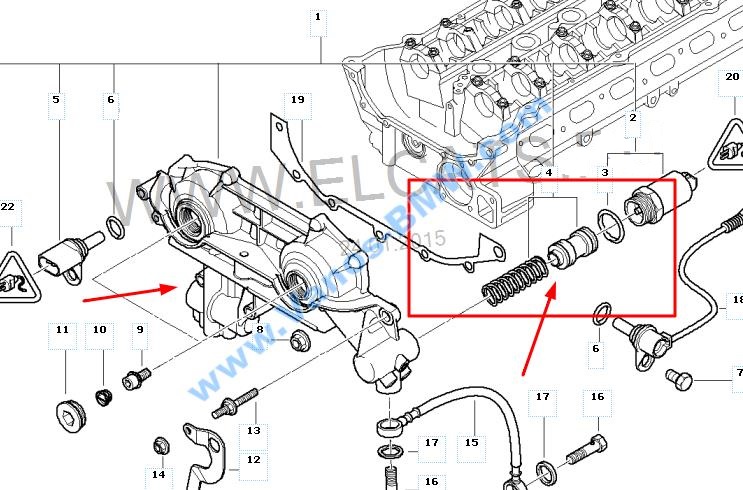

DME fault code 212 – VANOS: mechanical jamming and / or

– A slight loss of power and torque, and / or

– Irregular idling and / or

– Knock on the area of the actuator the VANOS

Likely causes:

1. Broken cable to the solenoid valve. This damage (open / cable bleed) is possible, as a rule, when unqualified disassembling the cylinder head.

2. The formation of burrs / chips on the edge of the control of the control piston VANOS. (circled in red).

3. Formation of burrs / chips in the vanos cylinders (cause worn seals and broken dial-bearing bringing pistons vanos warps).

4. Foreign bodies / dirt in the area of the control piston VANOS.

5. The actuator is installed with the VANOS mistake on one tooth.

solution:

1. Restore the wiring.

2. Remove the solenoid valve VANOS.

Push the finger control piston VANOS. Control piston should be pressed without binding / jamming. The strength of the spring must be at release push the piston back. Dent to a depth of no more than 10 mm (for the control piston). If it does not, replace the VANOS control piston or treat fine sandpaper edge of the control piston to eliminate jamming (remove a small facet). Remove “burrs” inside the control cylinder can be rolled into a tube (outside abrasive layer) sandpaper (after the procedure, be sure to rinse the entire actuator assembly vanos (such as gasoline).

3. If the bully small sanded with fine sandpaper (2000) to eliminate scuffing, be sure to replace the O-ring and metal ring inlaid bearing !!!.

4. Clean the dirt.

5. Adjust the mechanism vanos.

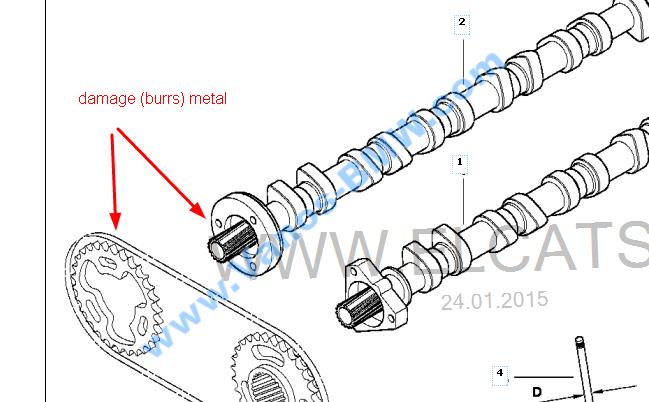

Problem number 4 – Mechanical jam 2

– Partial or complete performance of the system is not Vanos BMW

The Reason:

1. Formation of burrs / scratches on the flange camshaft (indicated by red arrow).

mechanical jamming vanos

solution:

1. Sanding teaser (burrs), sand with fine sandpaper to eliminate scuffing camshaft flange and the star.

Problem number 5 – Or what if driving with a defective Vanos

What happens if during the repair on Vanos BMW?

In addition to the poor performance of the engine and the noise continued operation of cars with faulty Vanos entail deterioration of the splined shaft and the star (will play). As a result, the resulting backlash will affect the position of the camshaft and as a consequence of the wrong degree of opening (closing) valves.

As a result of vibration at idle, sluggish traction, increased consumption, crashing, unstable start the engine bay candles, detonation, and more.

In this regard, we recommend not to delay the repair vanos. And if you’ll notice when changing play in the splined shaft connection and the stars, it is recommended to replace them too, after this procedure and the correct installation of the camshaft, you do not know your BMW:-)